Global Supply Chain Solutions and Comprehensive Procurement of Fasteners

Industrial Fasteners, Aerospace & Defense Fasteners, Specialty Hardware. Serving distributors, manufacturers, defense contractors, aerospace MRO providers, government & international sales.

Strategic Sourcing Partner for Critical Industries

U.S. Fastener Import & Trading Company (USFITC) is a Los Angeles-based importer and exporter of fasteners and specialty hardware, sourcing components from leading global manufacturers for customers in the United States and worldwide.

We represent select global fastener manufacturers across key industries, including automotive, construction, electronics, marine, renewable energy, and medical devices. We connect businesses with trusted suppliers to ensure operational continuity and product reliability.

Our end-to-end procurement service includes factory-direct pricing, order management, import logistics, shipping coordination, and final delivery. We create dependable supply chains tailored to your unique fastening requirements.

Partner with us for seamless, cost-effective, and reliable sourcing.

Our Services

-

One-Off Sourcing

Quick, on-demand sourcing of fasteners for transparent pricing. Ideal for urgent or low-volume needs.

-

Monthly Sourcing Support

Reliable monthly sourcing and coordination for distributors and OEMs with steady demand. Streamline procurement with dedicated support.

-

Custom Project Sourcing

Tailored sourcing for specialized engineered fasteners in industries like aerospace, EV, data center, and electronics. We handle the hard-to-find.

Export Compliance

We are committed to full compliance with U.S. export control laws, including the International Traffic in Arms Regulations (ITAR) and the Export Administration Regulations (EAR). We work closely with advisors and attorneys to ensure that all controlled exports are properly classified, licensed, and shipped in accordance with applicable U.S. regulations.

Delivering Precision: Fasteners For a Wide Range of Applications

We source standard and OEM fasteners to meet procurement requirements across a wide range of industries. OEM fasteners are manufactured to your exact design specifications, ensuring precision, compatibility, and performance.

Standard fasteners are sourced from trusted suppliers in allied nations to meet quality, cost, and lead time expectations. For custom or specialty fasteners, we work with qualified international partners or domestic U.S. manufacturers, based on sourcing criteria and cost-effectiveness. Aerospace and military-spec fasteners are procured exclusively from U.S.-based suppliers and manufacturers.

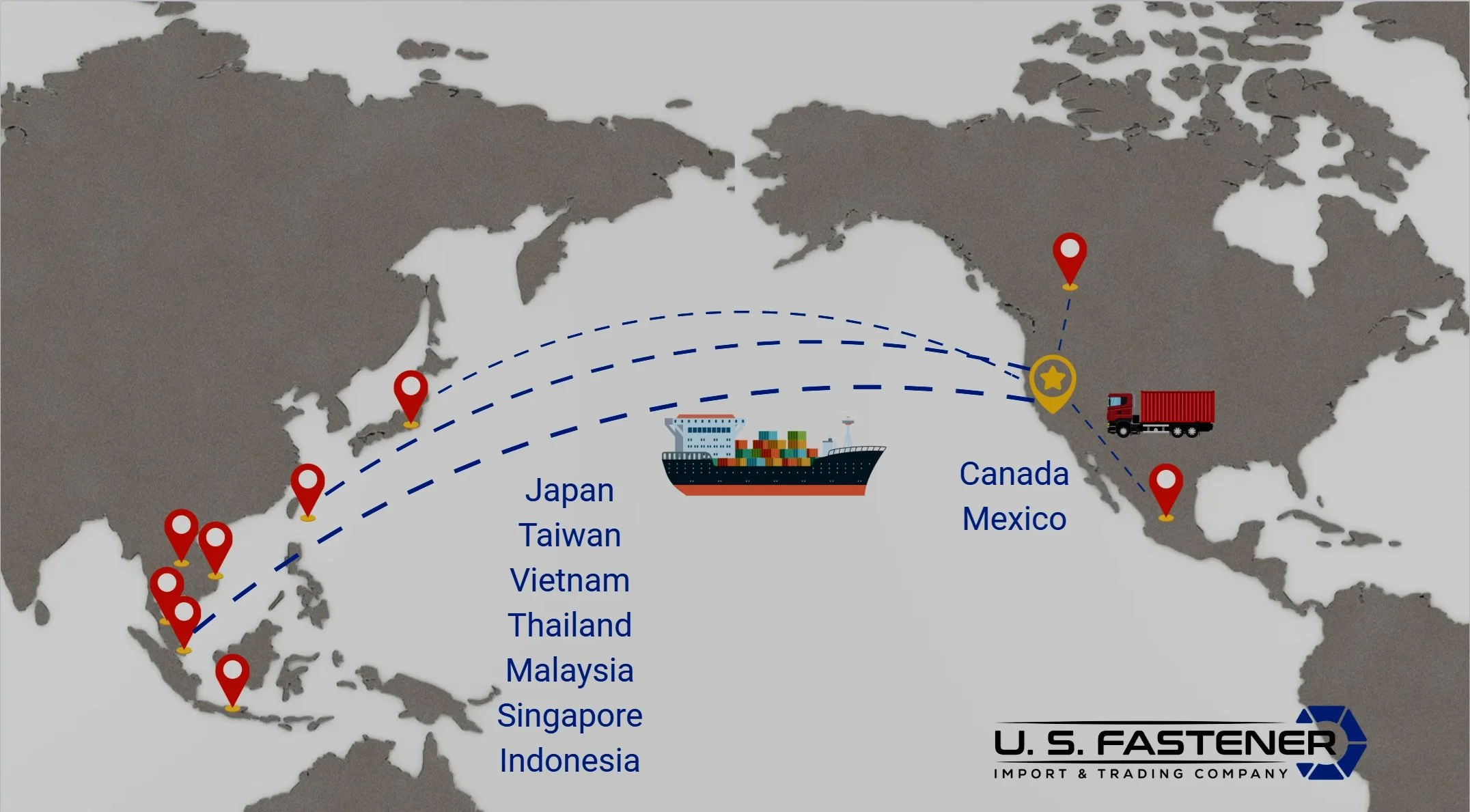

Proximity to the Port of Los Angeles and Access to the Pacific Rim.

Located in the Los Angeles area, we enjoy close proximity to the bustling Port of Los Angeles, Port of Long Beach, and easy access to the dynamic Pacific Rim economies. This strategic advantage allows for efficient goods handling, reduced costs, and a diverse range of high-quality fasteners to meet the ever-evolving needs of our customers.

Quality, Precision, Service

Our goal is to provide products with unparalleled quality, reliability, and precision. Our expertise in sourcing and importing fasteners, along with our commitment to exceptional customer service, enables us to consistently meet the stringent requirements from clients.

By partnering with us, you can expect prompt delivery, competitive pricing, and a seamless supply chain experience.